1 Micron Polypropylene Wound Cartridge 10” L DOE Polypropylene Core

$3.10

- SKU:

- E-SWPP-0100-10

Custom Filtration Solutions wound cartridges are manufactured in microfiber yarn that's structured with a graded density for economical micronic particulate retention performance in high-purity fluid filtration applications. The use of precision winding patterns provides consistent product quality and performance. Design rated for efficiency of up to 80%.

Available in all common ratings and materials of construction.

Features

- Polypropylene option offers durability and inertness. Complies with US FDA and EU regulations for safe use with food products and potable water

- Cotton and glass fiber options offer greater operating temperature tolerance.

- Controlled porosity delivers fine retention & capacity

- No glues, resins, or chemical additives used

Applications

- Food products & ingredients; bottled water

- RO prefiltration

- Process water; wastewater

- Plating solutions

- Fine chemicals

- Industrial oils; edible oils

Product Quality

- Manufactured within an ISO 9001:2015 certified quality management system.

- Certificate of Quality available upon request for each product lot.

Materials of Construction

| Media: | Polypropylene, Cotton, Glass Fiber |

| Core: | Polypropylene, Stainless Steel |

Dimensions

| Diameter: | 69mm (2.5") |

| Lengths: | 10”, 20”, 30”, 40” |

Operating Conditions

| Operating Temperature: | 80°C (176°F) max. (polypropylene) |

| Operating dP (max.): | 120°C (248°F) max. (cotton/SS), 200°C (390°F) max. (glass fiber/SS) |

| Change-Out dP: | 2 bar (30 psi) @ 20°C (68°F) |

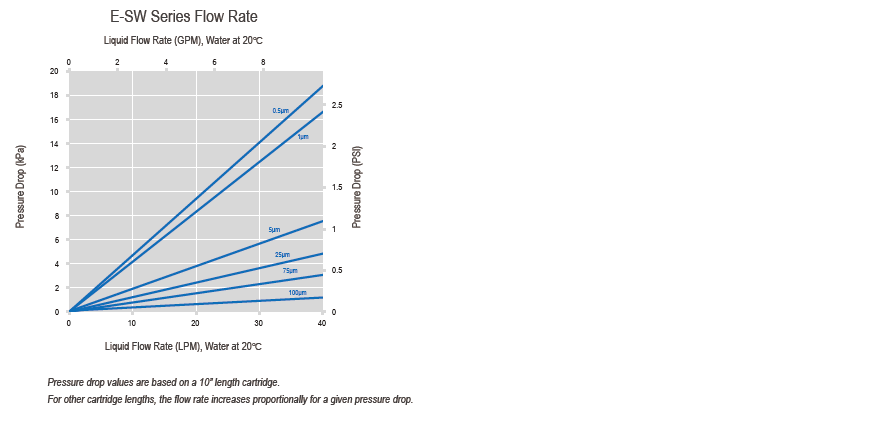

Clean Pressure Drop

Note: Additional materials of constuction may be available. Please inquire.

Write a Review

1 Micron Polypropylene Wound Cartridge 10” L DOE Polypropylene Core