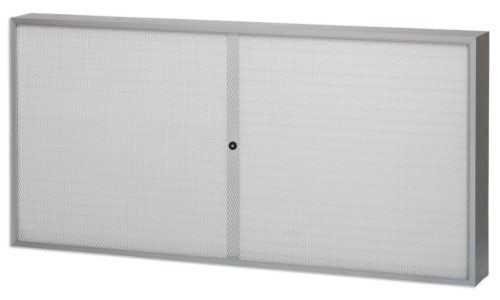

Cleanroom Air Filters

Cleanroom Air Filters are a vital component in maintaining optimal performance across various industrial applications. These high-quality filtration solutions are designed to meet the rigorous demands of MRO buyers, OEMs, and maintenance and engineering professionals. With their superior capabilities, they can significantly enhance system efficiency, reduce operational costs, and ensure a clean and safe working environment. Explore our selection for the ideal choice that fits your specific needs.

Cleanroom Air Filters: Ensuring Pure Air for Your Specific Needs

Whether you're running a high-tech lab or a pharmaceutical facility, cleanroom air filters are an essential component to maintaining a sterile environment. These specialized filters are designed to remove tiny particles from the air, preventing contamination and ensuring the integrity of your work. Understanding the importance of choosing the right filter can make a significant difference in the overall efficiency and effectiveness of your cleanroom operations.

Before making a purchase, consider these key factors:

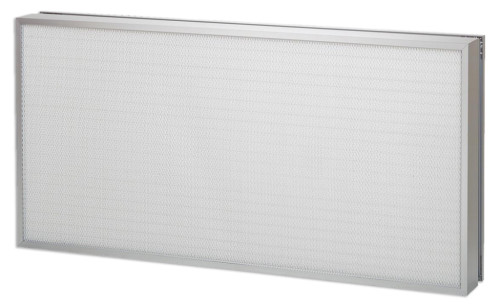

- Filter Efficiency: Different filters have different efficiencies. Higher efficiency filters are capable of eliminating smaller particles. Consider your requirements and choose a filter with an efficiency rating that suits your needs.

- Size and Fit: Filters come in various sizes. Ensure that the filter you choose fits your system correctly. An ill-fitted filter can compromise the cleanliness of your cleanroom.

- Material: The durability and effectiveness of filters depend largely on their material. Some filters are made with synthetic media for enhanced performance, while others use traditional fiberglass.

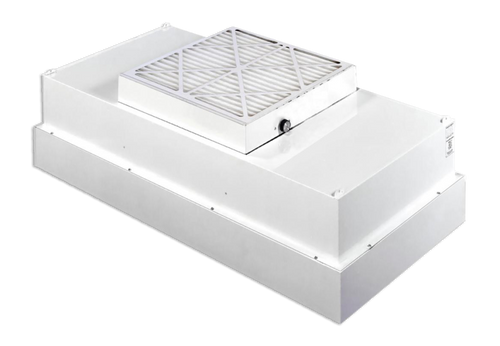

- Maintenance: Consider the maintenance requirements of the filter. Some filters may need more frequent replacement or cleaning than others.

- Cost: While quality should be a priority, it's also important to consider cost. Balance your budget with your specific needs to make a wise buying decision.

Choosing the right cleanroom air filter is crucial for maintaining a controlled environment. By considering factors like efficiency, size, material, maintenance, and cost, you can ensure that you're selecting the best filter for your cleanroom. Remember that the right filter not only ensures the purity of your environment but also contributes to the success of your operations.

Ready to make your purchase? Browse through our extensive range of cleanroom air filters and find the perfect fit for your needs. Our expert team is always available to assist you in making the right selection. Shop now and experience the difference of a properly filtered cleanroom!