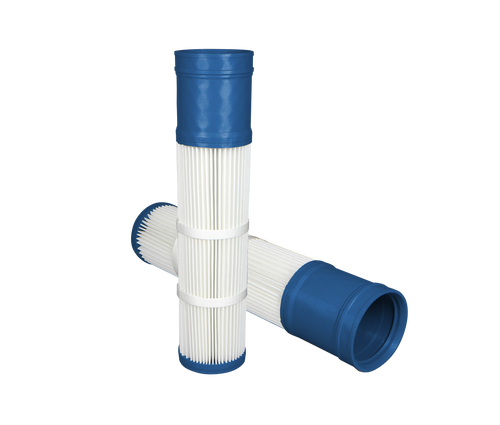

Pleated Filter Bags

CFS manufactures pleated bag filter elements to replace traditional fabric bags in industrial baghouses (horizontal or vertical mount). Pleated bags increase filtration area in the same space, improve dust release, and can reduce pulse frequency and energy use compared with standard felt bags.

What Is a Pleated Bag?

A pleated bag is a one-piece filter element that installs where a standard fabric bag and cage would normally go. The pleated media is bonded to a molded or metal end cap and supported by an internal core, so it replaces both the bag and the cage. Typical media is spun-bond polyester with optional surface treatments. Benefits include more filtration area per element, lower operating differential pressure, faster change-outs, and excellent dust release.

Key Features & Benefits

- Spun-bond polyester media for high collection efficiency and excellent dust release.

- Increased filtration area versus standard bags; operate at lower air-to-cloth ratios.

- Reduced pulse cleaning frequency and energy usage; lower system differential pressure.

- Rugged construction with spiral helix core for strength and durability.

- Configurable pleat counts and element lengths to match collector and airflow needs.

- Top-load and bottom-load designs; drop-in replacements for many OEM housings.

- Grounding/anti-static options available for combustible dust applications.

Pleated Bag Series

The series below cover common interface styles found in industrial baghouses.

| Series | Mount / Interface | Nominal Diameter | Typical Top / Bottom | Notes |

|---|---|---|---|---|

| 2ST — Two-Stud Top | Top-load; two-stud cap pattern | 6 in (nominal) | Two-stud top cap / sealed bottom | Adapts to many common 6″ tube sheets; quick change-out. |

| UBL — Universal Bottom-Load | Bottom-load; molded end | ≈5.75 in (nominal) | Molded top with clamp interface | Fits many bottom bag removal collectors. |

| LBB — Long-Boot Bottom-Load | Bottom-load; long boot | Varies by collector | Long boot / clamp | One-piece element eliminates separate cage; faster change-outs. |

Media, Treatments, and Construction Options

| Category | Options | Typical Advantages |

|---|---|---|

| Filter Media | Spun-bond polyester (standard); specialty media by request | High efficiency, durable, good dust release |

| Surface Treatments | Oleophobic/hydrophobic, anti-static, PTFE membrane (selected styles) | Improved release, lower differential pressure, static control, fine dust capture |

| Top/Bottom Styles | Two-stud top, molded universal bottom-load, long-boot bottom-load | Drop-in compatibility with many OEMs; faster change-outs |

| Core / Support | Spiral helix core (standard); metal or polymer options | Strength and durability under pulsing |

| Grounding | Stainless ground wire or conductive treatments | Static dissipation for combustible dust service |

Typical Applications

- Powder coating, metalworking, welding fume

- Minerals, cement, lime, and aggregate processing

- Food, grain, and feed handling (verify compliance requirements)

- Plastics compounding and conveying

- Woodworking and furniture manufacturing

- Thermal spray and blasting operations

How to Specify a Pleated Bag Replacement

Information to Provide

- Collector make/model or existing element part number.

- Tube-sheet hole size, center-to-center spacing, and quantity.

- Mounting style (top-load or bottom-load) and interface (two-stud, molded, boot, clamp, etc.).

- Overall length, outside diameter, and required pleat count (if known).

- Operating temperature, humidity, dust characteristics, and any NFPA/ATEX requirements.

- Preferred media/treatments (e.g., anti-static, PTFE membrane) and grounding option.

Why Choose CFS Pleated Bags

- Made-to-order elements to meet or exceed OEM fit and performance.

- Broad coverage of top-load and bottom-load interfaces including 2-stud, universal, and long-boot styles.

- Application support to match media and treatments to your dust and duty cycle.

- Fast lead times on common sizes; expedition available.

Request a Quote

Ready to upgrade to pleated bags or replace existing elements? Provide your dimensions and operating details and a CFS specialist will confirm the correct series, media, and options. Contact Custom Filtration Solutions.