Liquid Filter Cartridges

Liquid filter cartridges are used to remove particulate, gels, and microorganisms from process fluids across industrial, commercial, and sanitary applications. Below are the primary cartridge types we offer, with common materials, micron ratings, sizes, and typical uses to help you choose the right technology for your system.

Refine:

Depth Filter Cartridges

Depth filters capture contaminants throughout the thickness of the media, offering high dirt-holding capacity and long service life. They are ideal as prefilters or polishers where cost-effective, robust filtration is required.

Common Applications

- Process water, cooling water, RO prefiltration

- Chemicals, solvents, paints and inks

- Food and beverage clarification

- General industrial fluids and oils

Materials, Ratings, and Sizes

| Media | Core | Micron Ratings | Lengths | OD / ID |

|---|---|---|---|---|

| Polypropylene, Cotton, Polyester | PP, 304SS, 316SS, Tin-plated Steel | 0.5–100 µm (nominal) | 9 ¾", 9 ⅞", 10", 20", 30", 40" | 2.5" OD (typ.), 1.0" ID |

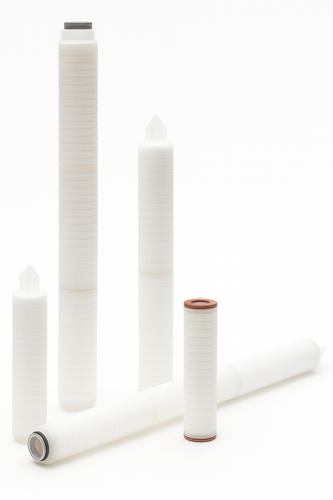

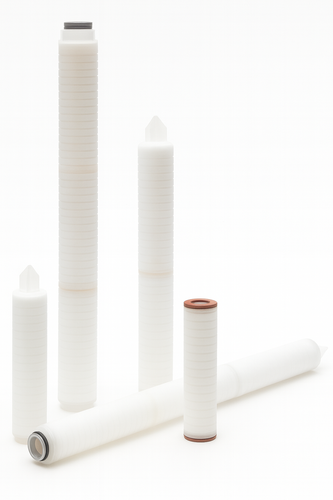

Pleated Filter Cartridges

Pleated cartridges provide high surface area for lower pressure drop and longer life at finer micron ratings. They are suited to applications needing consistent efficiency and higher flow at a given size.

Common Applications

- Fine clarification and final filtration of water and chemicals

- Food and beverage polishing

- Electronics and plating baths

Materials, Ratings, and Sizes

| Media | End Configurations | Micron Ratings | Lengths | OD / ID |

|---|---|---|---|---|

| Polypropylene, Polyester, Glass Fiber | DOE, 222/226 with Fin or Flat, SOE with Spring | 0.2–100 µm (nominal and absolute options) | 9 ¾", 10", 20", 30", 40" | 2.5" OD (typ.), 1.0" ID |

Membrane Filter Cartridges

Membrane cartridges provide precise, absolute-rated retention using microporous membranes. They are selected for critical applications requiring validated microbial or particulate reduction.

Common Applications

- Sterile filtration in beverage and biotech (post-heat or cold sterile)

- Final filtration of ultrapure water and high-purity chemicals

- Pharmaceutical and laboratory processes

Materials, Ratings, and Sizes

| Membrane | Supports/Hardware | Micron Ratings (absolute) | Lengths | End Connections |

|---|---|---|---|---|

| PES, PTFE, Nylon, PVDF | Polypropylene or PVDF components | 0.03–5.0 µm (application dependent) | 10", 20", 30", 40" | 222/226 O-ring with Fin/Flat, DOE |

Stainless Steel Filter Cartridges

All-metal cartridges tolerate high temperature, differential pressure, and aggressive fluids. Cleanable and reusable, they offer low lifetime cost in demanding services.

Common Applications

- Hot oils, amines, solvents, steam and gases

- Catalyst recovery and high-temperature service

- Corrosive or oxidizing environments

Materials, Ratings, and Sizes

| Construction | Alloy Options | Micron Ratings | Lengths | Cleaning |

|---|---|---|---|---|

| Sintered metal fiber or mesh, pleated or cylindrical | 304SS, 316LSS (others by request) | 1–200 µm (absolute or nominal) | 10", 20", 30", 40" (custom on request) | Backwash, ultrasonic, chemical clean |

Carbon Filter Cartridges

Carbon cartridges remove chlorine, taste and odor, and certain organics by adsorption. Available as extruded carbon block or granular activated carbon (GAC) designs.

Common Applications

- Chlorine reduction for RO prefiltration

- Taste and odor improvement in beverage and potable water

- Organics reduction in process water

Materials, Ratings, and Sizes

| Type | Media | Ratings | Lengths | Diameters |

|---|---|---|---|---|

| Carbon Block, GAC | Activated Carbon (coconut shell or coal) | 1–20 µm (nominal), chlorine reduction rated | 9 ¾", 10", 20" | 2.5" OD and 4.5" Big Blue |

High Flow Cartridges

High flow cartridges deliver very high flow rates with fewer elements per housing, lowering footprint and changeout time. Large-diameter, pleated designs keep pressure drop low.

Common Applications

- High-volume process water and cooling loops

- Desalination pretreatment and intake water

- Refining, petrochemical, and power generation

Materials, Ratings, and Sizes

| Media | Configuration | Micron Ratings | Lengths | Diameters |

|---|---|---|---|---|

| Polypropylene, Polyester, Glass Fiber (pleated) | Large OD single-open-end with O-ring | 1–100 µm (absolute and nominal) | 20", 40", 60" | 6"–8" OD (system dependent) |

Selection Guidance

How to Choose

- Contaminant type: Use carbon for chlorine/organics; membrane for microbial control; pleated for fine particulates at lower DP; depth for high dirt loads; stainless for high temp/pressure.

- Chemical compatibility: Match media and hardware to the fluid and temperature.

- Target quality: Absolute-rated membrane for critical service; nominal-rated pleated or depth for general use.

- Operating cost: Balance cartridge life, changeout frequency, and energy from pressure drop.

Request a Quote

Provide fluid, temperature, viscosity, flow rate, desired micron rating, cartridge length and end connection, and any regulatory requirements. We will confirm compatibility, efficiency, and lead time, and recommend the most cost-effective solution.