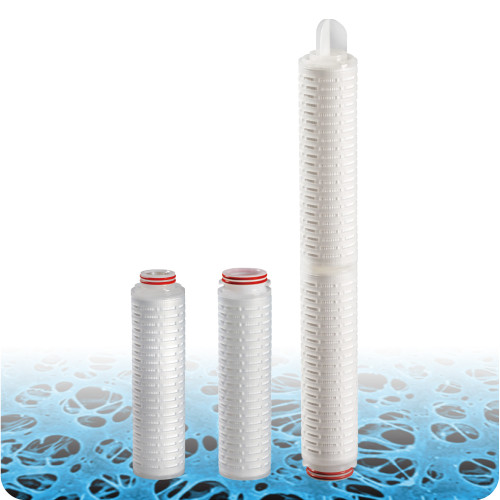

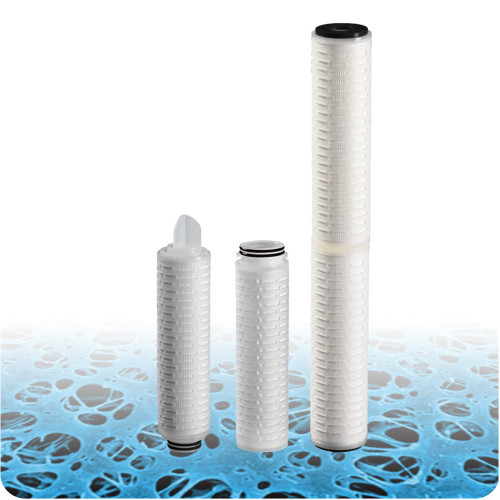

PES Series Beverage Grade PES Pleated Filter Cartridges

(331) 215-4119

- Other Seal Materials Available:

- EPDM, Buna,

CFS-PES Series polyethersulfone pleated filter cartridges provide efficient submicronic retention in the production of foods and beverages. The highly asymmetric PES membrane gives excellent permeability, contaminant capacity, and particle removal at high flow rates and low pressure drop. Excellent microbial retention with proven high LRV performance. Being hydrophilic, cartridges allow for fast and easy wetting in aqueous fluids. Cartridges are 100% integrity tested to assure optimized retention performance. Component materials comply with US FDA and EU regulations for safe use with food and potable water.

Optional serial-layered grades offer greater LRV performance and tolerance to steam sterilization for extended service life.

Features

- Durable PES and polypropylene components

- Extreme porosity highly asymmetric membrane

- Excellent fluid compatibility

- UPW rinse assures low extractables

Applications

- Beer, wine, distilled spirits

- Bottled water production

- Food oils

- Fruit juices

Product Quality

- Individual elements are identified by serial number.

- Produced in a clean-room environment for product purity & cleanliness.

- Manufactured within an ISO 9001 certified quality management system.

- 100% integrity tested by diffusion flow.

- Meets USP Biological Reactivity Test requirements of the current USP <88> for Plastics Class VI-121°C.

- A Certificate of Quality document is provided with each production lot.

Microbial Retention Performance

| Rating | Microbial Retention |

| 0.2μm | Brevundimonas diminuta (ATCC 19746), >7 LRV |

| 0.45μm | Serratia marcescens (ATCC 14756), >6 LRV |

| 0.65μm | Saccharomyces cerevisiae, >5 LRV |

Materials of Construction

| Media | Polyethersulfone |

| Support Layers | Polypropylene |

| Cage/Core/End Caps | Polypropylene |

| Adapter Reinforcement | Polysulfone or Stainless Steel |

| Seal Options | Silicone, NBR, EPDM, FKM, E-FKM |

Dimensions

| Diameter: | 69mm (2.72") |

| Lengths: | 10”, 20”, 30”, 40” |

Operating Conditions

| Operating Temperature: | 80°C (176°F) max. |

| Operating dP (max.): | 4 bar (58 psi) @ 20°C (68°F) 2 bar (29 psi) @ 80°C (176°F) |

| Change-Out dP: | 2.6 bar (38 psi) @ 20°C (68°F) |

| Sterilization Recommendations | |

| Autoclave | 125°C (257°F), 30 minutes, 30 cycles |

| Steam-in-Place (SIP): | 125°C (257°F), 30 minutes, 30 cycles |

| Extractables, typical | |

| Per 10” element: | ﹤25mg non-dissolved solids |

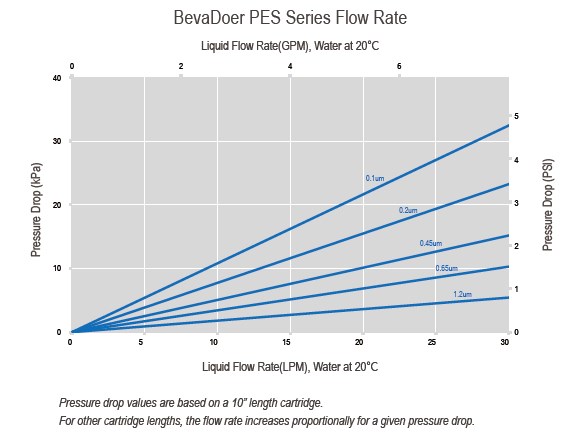

Clean Pressure Drop

Effluent Quality

- Non-fiber releasing; Non-pyrogenic

- Effluent meets USP Purified Water requirements for TOC, pH, and water conductivity

Write a Review

PES Series Beverage Grade PES Pleated Filter Cartridges